Aeration pads and inserts - Siperm R, Siperm B, Siperm HP

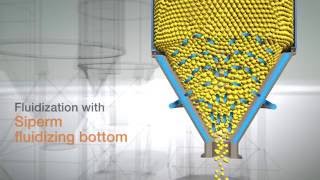

Problems are often experienced when handling powdery and fined-grained bulk materials, such as flour, cement, pigments or fine plastic powders. Storage, mixing and discharge are difficult because these fine-grained powders do not flow freely. They tend to agglomerate and form bridges or tunnels around the silo outlet and, therefore, can only be removed effectively using some sort of discharge aid.

A highly efficient solution to these problems are pneumatic Siperm-aeration components. They are supplied complete with all the necessary hardware (seal, washer, nut) and can also be retrofitted into existing systems.

Ready-to-install aeration pads are supplied complete with all the necessary hardware (seal, washer, nut). They are ideally suited for installation at those sites where access is limited or difficult. The pads are available as standard in sizes of 125 x 250 mm and 125 x 500 mm. Of course we also manufacture pads in special sizes.